Advantages of an Agitated Nutsche Filter Dryer

Mar 15, 2024

Every industry has its intricacies.

Often so, they include equipment that’s only used in specific industries. It’s the same with pharmaceutical manufacturing. Among the many sets of specialized manufacturing equipment that the pharmaceutical industry has, one of the includes the agitated nutsche filter dryer (ANFD).

Let’s know more about agitated nutsche filter dryers and their advantages.

What are ANFDs?

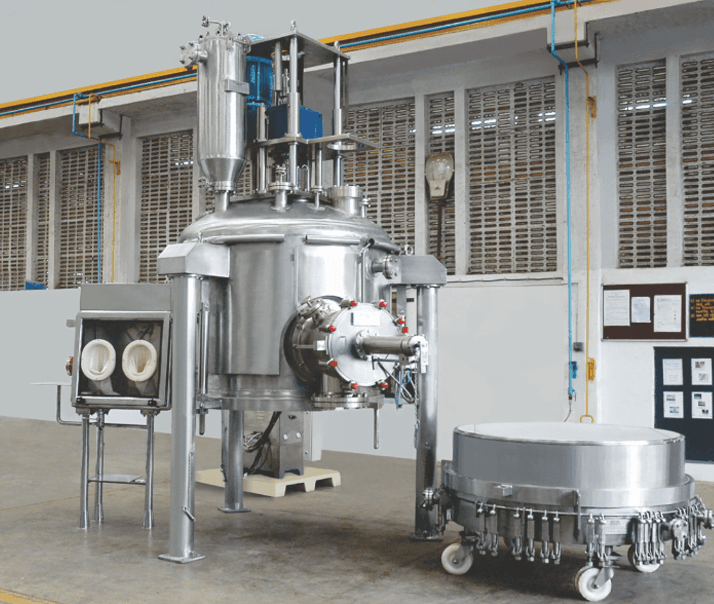

In the realm of API processing post-crystallization, ANFD is known for its versatility and efficacy. The humble yet power-packed ANFD is a piece of equipment that performs a variety of operations within a single vessel. This has revolutionized the process of batch processing in the pharmaceutical industry.

ANFD integrates the filtering, washing, re-slurrying and drying process for pharmaceuticals, thus eliminating the need for multiple equipment pieces.

Seamless Functionality

An agitated nutsche filter is a multi-functional apparatus enclosed within a vessel. They streamline the production process through the elimination of multiple pieces of equipment, further reducing batch processing time.

So, one ANFD will do the work for you – combining filtering, washing, re-slurrying and drying for a single batch. They’re proven to uptick operational efficiency while maintaining product quality and purity.

Versatile MOCs

MOC refers to material of construction.

ANFDs are made from top-quality materials such as stainless steel, Hastelloy and other nickel-based alloys. They’re also available in options such as cladded, polymer-lined or glass-lined construction. These versatile MOCs pave the way for enhanced compatibility with a wide range of chemical products.

Minimizing Product Loss

ANFDs minimize product losses during processing.

With the fully enclosed vessel design, it ensures precise control over filtering, washing and drying operations. This minimizes the risk of contamination or spillage, adding to the product quality and purity. Ultimately, this leads to cost savings and serves as a contributor to the overall efficiency.

ANFDs from Thermosag can help you save a good amount of money!

Conclusion

Agitated Nutsche Filter Dryers stand tall as specialized pharmaceutical equipments that strive to make a difference in the pharmaceutical industry. With its varied applications and multi-functional usage, it saves quite a lot of time and money.

With that, it also refuses to compromise a tad bit of quality. Thermosag is one of the leading providers of ANFDs. Check out our website to know more!